Cement Rotary Kiln Refractory Brick

CEMENT ROTARY KILN REFRACTORY LINING

The rotary kiln refractory lining is a layer of refractory material installed inside the kiln cylinder,which plays important role and is an important part in the cement rotary kiln.

As a supplier of refractory lining for the cement kiln,we provide products for each area of the kiln,including high alumina brick,magnesia chrome,magnesia bricks,castables,mortars.

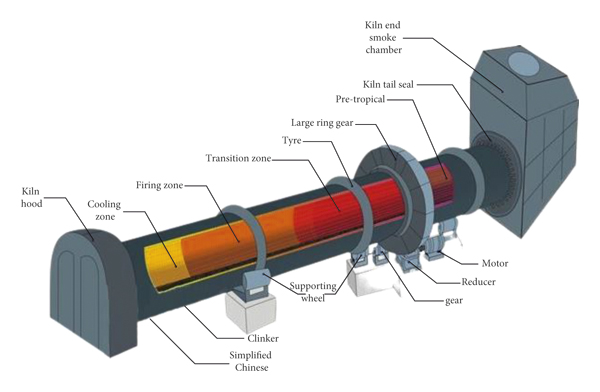

Cement Rotary Kiln Body Introduction

The cement rotary kiln body have different parts,these parts including preheating zone,lower transition zone,upper transition zone,sintering zone and cooling zone.Different zone have different length,temperature and usage.

How to choose refractory lining for cement rotary kiln?

Choosing the right refractory lining is important,as this not only ensure the smooth running of cement rotary kiln,but also extend the kiln service life.The refractories should according to the working environment in different parts of the rotary kiln body.

The refractory materials for rotary kiln should have strong resistance and good erosion,and the bricks meet the working environment requirements.

Preheating Zone

High alumina brick,phosphate alumina brick,anti-stripping brick or alkali resistant brick such as magnesia brick,magnesia spinel bricks usually used in this part.

Lower Transition Zone

The temperature in this zone is low,so it need low thermal conductivity brick for example anti stripping alumina brick or silica mullite brick.

Upper Transition Zone

This zone coating is not stable,the refractory lining should have good thermal resistance,good wear resistance and low thermal conductivity.For example,magnesia alumina spinel brick or silica alumina brick.As the thermal conductivity of silica alumina is lower,it have more better performance in reduce kiln shell temperature and prolong the kiln life.

Sintering Zone

This part has high temperature and strong chemical reaction,the refractory lining in this part should have good corrosion resistance.Usually in this zone,magnesia chrome brick,magnesia spinel brick or compound spinel brick are used in this area.

Cooling Zone

The temperatures have great change in this part.The refractories for this zone should have good wear resistance and thermal shock resistance.Anti stripping alumina brick or silicon mullite brick are good choice.Also it could use castable in this area,for example,corundum castable,mullite castables and high alumina castable with steel fiber.

The above we introduce refractories for each zone of the cement rotary kiln body,but this is according to the specific project,working environment,maintenance cost and so on.

REFRACTORY BRICKS INSTALLATION METHOD FOR CEMENT ROTARY KILN

It is necessary to ensure that the brick lining and the kiln body are reliably concentric during kiln operation.The basic requirements for laying bricks in the kiln are:

The brick lining is close to the shell, the bricks are tightly connected to each other.

The brick joints are straight, the intersection circles are accurate, the bricks are locked firmly, and not sagging out of the void.

The masonry must be carried out strictly according to the datum line, and it is strictly forbidden to lay bricks without setting the line.

A maximum of one steel plate is allowed in each joint, the narrow steel plate for adjustment should be used as little as possible, and the cardboard used for expansion joints should be placed according to the design

After the brick lining installation finished, the brick lining of the whole kiln should be thoroughly cleaned and tightened as necessary before ignition. It should be inspected ring by ring, tightened ring by ring, and the kiln should be kept clean,and should be ignited in time